You are here

History of development of Zhezkazgan deposit by British.

Ulytau mountains in Kazahstan.

“The most expressive in this regard is Dzhezkazgan himself. Where oxidized copper ores in ancient times were mined on a huge scale ... the most conservative estimates showed that at least a million tons of rich copper ores were mined from Dzhezkazgan in antiquity.”

K. A. Satpaev.

First British visits to Zhezkazgan deposit.

For the first time in 1903, the Zhezkazgan copper deposits were visited by the Englishman West, who gave them a high appraisal. In 1904, under an agreement with von Stein, exploration work began here, at the same time 21,000 pounds of copper ore were mined.

In 1904, the British became the owners of the Spassko-Uspensky copper mines and founded the Spassky Copper Ores Joint Stock Company. Subsequently, the British acquired the Zhezkazgan deposit for 260,000 rubles, as well as an iron mine in the Eskula tract, lime pits, Baikonur coal deposits, and the Karsakpai-Asha valley.

In London, the Atbasar Copper Ores Joint Stock Company was organized with a capital of 250,000 pounds sterling. In 1907, a lease was concluded with von Stein and industrial exploration began using diamond drilling.

The very first results amazed the experts: the ore contained from 6 to 32 percent copper. In the future, the British decided to subject the ore to analysis only if the determination by eye was in doubt. In 1908, the English engineer Harvey visited the Zhezkazgan field.

Upon his return to London, at a meeting of shareholders, he stated that the Zhezkazgan copper deposit is one of the largest in the world, the ore fields of which contain a huge amount of high-grade copper. In addition, there is a rich Baikonur coal deposit nearby, which can provide the required amount of fuel.

But a major drawback is the great remoteness from the railway. An optimistic report by an experienced English engineer accelerated the development of the Zhezkazgan copper deposit and attracted new shareholders to it.

Up to three hundred workers were involved in exploration work. At the same time, 440,000 pounds of copper ore were mined in 1907 - 1909. In January 1, 1909, the Ryazanovs transferred the Zhezkazgan copper deposits to von Stein for 260 thousand rubles.

In the same year, a joint-stock company of Atbassar copper ores was organized in London with an initial capital of 250 thousand pounds sterling. Arthur Fell became chairman of the board, and Alexander Davidson became director.

The shares were placed in England. Engineer Algernon Nobel was invited to provide technical guidance for the development of the field. In 1908, the American experts Titcomb and Simon visited the Zhezkazgan deposit, and they also described the deposit as “unique”.

And American entrepreneurs also invested their capital in the Atbasar business. Intensive exploration work was carried out. Only in 1910, 68 wells were drilled, of which 42% yielded rich ores and a large ore body. 13 exploration mines were laid.

The directors and main shareholders of the "Joint-Stock Company of Spassky Copper Ore" were members of the "Joint-Stock Company of Atbasar Copper Mines". By the beginning of 1911, 40 percent of the shares of the Atbasar enterprise were in the hands of the Spassky Company.

Recognizing the enormous value of the Zhezkazgan copper deposits, in 1913 the board of the Joint Stock Company of the Spassky Copper Ore acquired a controlling stake in the Joint Stock Company of the Atbasar Copper Mines.

As a result, in addition to the Spassko-Voskresensky copper mine with a copper smelter, the Uspensky copper mine, the processing plant at Sary-Su, the Saransk and Karaganda coal mines and two Sasyk-Karasu iron mines, the Spassky Copper Ruds joint-stock company became the owner of 21 allotments for copper mines in the Zhezkazgan tract, one iron mine in the Eskula tract, 18 lime quarries, 20 allotments of coal mines in Baikonur with an area of 23 sq. km and the construction of the Karsakpai copper smelter, which began to be built - all with a total area of 4196 acres.

At the end of December 1912, at a meeting of shareholders, it was decided to build a copper smelter in the spurs of the Ulytau ridge, in the Karsakpai tract on the left bank of the Kumola River, according to the Perkins project.

Here the river made a loop. The project was to block the river with a small dam and create a reservoir. At 40 versts from this tract it was discovered deposit of fluxes, which made it possible to reduce the cost of their delivery.

Already in 1914, it was planned to smelt 5,000 tons of copper (300,000 poods). By the spring of 1915, 235 wells had been drilled, over half a million tons of ore with an average copper content of 10.7% had been explored. To provide the plant with ore, 18 mines were laid.

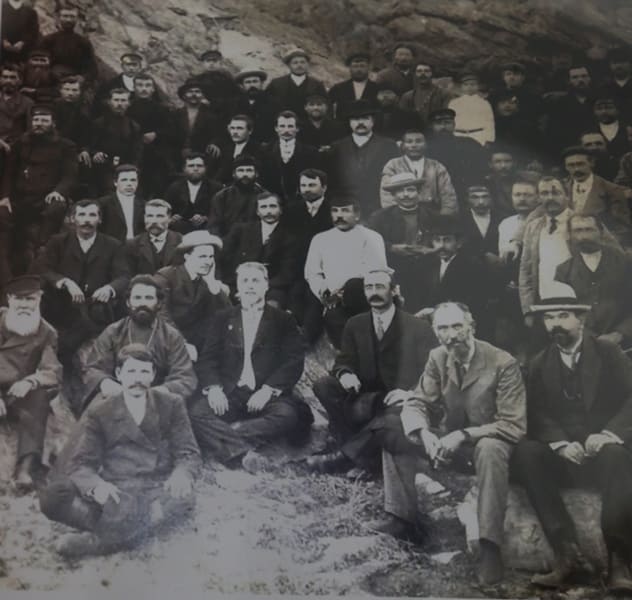

In the spring of 1913, about 300 workers arrived in Karsakpai. Every month their number grew in Karsakpai, and at the Zhezkazgan mine, and at the Baikonur mines, reaching 1,200 people. Work began with the preparation of building stone.

For this purpose, a brick factory was built. By the end of the year, several pits were dug for production facilities and 15 mud houses were built. In 1914, 2 more residential buildings and some production facilities here built - a power station, a mechanical workshop, warehouses, etc.

At the same time, exploration work was carried out. From 1907 to 1915 The British drilled 135 wells in Dzhezkazgan with an average depth of 60 m on an area of 90 acres. Explored reserves of copper have already ensured the operation of the plant for 12 years, although exploration covered only a seventieth part of the area of the main outlets.

Moreover, only ore with a copper content of at least 10 percent was taken into account. At the same time, the company in Baikonur conducted exploration for coal. Here, in six years, 54 wells were drilled, two working formations were identified.

The shallow depth of occurrence made it possible to develop the upper layer with small mines equipped with wooden pile drivers and horse-drawn gates. The smallest mines were served by manual gates. By 1918, the explored reserves of coal were sufficient for the operation of the plant for 12 years.

Experimental work was also carried out in order to determine the optimal methods for enrichment and processing of Dzhezkazgan ore. For this purpose, in May 1916, 1,124 poods of ore were transported by carts to the Sary-Suu concentrating plant.

Experimental work on the enrichment of Dzhezkazgan ore in the factory gave good results and served as the basis for the design of an enrichment plant with the production of thirty percent copper concentrate, which should enter the reverberatory furnace of the metallurgical plant.

Here, melting should be carried out on the gas of generators operating on Baikonur coal with the addition of fluxes. With the subsequent conversion of the matte, that is, its purification from the admixture of sulfur and iron, blister copper was obtained.

With the outbreak of the First World War, demand and prices for copper increased dramatically. This accelerated the construction of a copper smelter in Karsakpai. In the summer of 1915, the installation of trusses and ceilings for the smelter and processing plant began.

Construction was significantly hampered by the lack of a railway. It was necessary to connect the coal mines and mines with the plant with a railway track. ransportation by cart to Karsakpai of ore from Dzhezkazgan and coal from Baikonur amounted to 14 kopecks per pood.

In order to connect the mine and mines with the plant by rail, after survey work, in the spring of 1915, the construction of a narrow-gauge railway with a total length of 120 versts began. Stations were built in Karsakpai, Baikonur, Dzhezkazgan.

It was necessary to connect the Atbasar industries with the Tashkent railway, the nearest station of which was Dzhusaly (Zhosaly). This transshipment base is located 400 kilometers from Karsakpai. Here the British rented a plot, built warehouses, workshops, living quarters. About 1,000 wagons were purchased to transport goods to the plant.

Carriers from the local population with their camels and horses were hired to transport goods. Along the road, after 15-20 kilometers, pickets were set up with the necessary supply of food, water, and fodder. The delivery of one pood of goods cost the Society 60 kopecks.

The Dzhusaly station, several hundred thousand poods of various large-sized cargoes accumulated - equipment for the Karsakpai plant, which could not be transported by horse-drawn transport. It was necessary to build the Jusaly - Karsakpai railway, which required huge capital expenditures.

The British went the other way. From the Dzhusaly station on the way to Karsakpai, the first 13-verst section of the railway was laid. Five steam locomotives and 278 wagons were mounted on it, which took 2.5 versts of the way.

The wagons were loaded with 200,000 pounds of cargo. After the rolling stock was moved to the front end of the railway, the free 10.5 km of the rail track were remounted, and the caravan of steam locomotives and wagons advanced another 10.5 kilometers to Karsakpai.

Thus, the British expected to cover the entire journey in a year. The caravan set off on November 10, 1914, and arrived in Karsakpay on October 8, 1917, that is, three years later. Arrived equipment began to hastily install.

However, the revolution and subsequent civil war radically changed the course of events. The British failed to complete the construction of the Karsakpai plant. He They left the Kazakh steppes for a long time. The copper smelter of the joint-stock company "Atbasar copper ores" (a company founded by the British) started working only in 1928.

Authority:

Novikov Vladimir Yakovlevich.

http://novikovv.ru/kanish-satpaev/nachalo-zhezkazgana